-

Composite Wire

The combined conductor is a winding wire composed of several winding wires or copper and aluminum wires arranged according to the specified requirements and wrapped by specific insulating materials.

It is mainly used for winding of oil immersed transformer, reactor and other electrical devices.

Budweiser electric specializes in the production of copper and aluminum conductor paper-clad wire and composite wire. The overall dimension of the product is accurate, the wrapping tightness is moderate, and the continuous jointless length is more than 8000 meters.

-

NOMEX paper covered wire

NOMEX paper wrapped wire electrical, chemical and mechanical integrity, and elasticity, flexibility, cold resistance, moisture resistance, acid and alkali corrosion, will not be damaged by insects and mold. NOMEX paper – wrapped wire in the temperature is not higher than 200℃, the electrical and mechanical properties are basically not affected. So even if the continuous exposure to 220℃ high temperature, can be maintained for at least 10 years for a long time.

-

Transposed cable

Transposed cable is made of a certain number of enameled flat wires arranged in two columns in sequence by special technology, and made of special insulating materials

-

Electrician Laminated Wood

Laminated wood is widely used in insulation and support materials in transformers and transformers. It has the advantages of moderate specific gravity, high mechanical strength, easy vacuum drying and easy machining. Its dielectric constant is close to that of transformer oil, and its insulation is reasonable. It can be used for a long time in transformer oil of 105℃.

-

Electrical Soft Composite Materials (dmd, Etc.)

Electrical soft composite materials include E, B, F, and H grades with good mechanical strength. Dielectric properties and reliable thermal adhesion. The E grade includes composite paper; the B grade includes DMD, DMDM, DM; the F grade includes F grade DMD; the H grade includes NHN and NMN. It is widely used in power generation equipment such as slot insulation, turn-to-turn insulation and gasket insulation of transformers, power transmission and transformation equipment, traction locomo tives, motors, electrical appliances and electronics.

-

Insulation Paper Coated With Epoxy (full Adhesive Paper)

An insulating material made of cable paper as a substrate and a special modified epoxy resin coated on cable paper. The coil has a very good ability to resist axial short-circuit stress; improving the perma nent impact resistance of the coil against heat and force is beneficial to the life and reliability of the trans former.

-

Crepe Paper Tube

The crepe paper tube is made of electrical wrinkle insulation paper by special processing, and is mainly used for the insulation wrapping material of the inner wire of the oil immersed transformer. It is mainly used for high and low taps in the oil-immersed transformer body and soft wrinkle paper sleeve for screw outer insulation. It has reliable flexibility and excellent bending and bending in any direction.

-

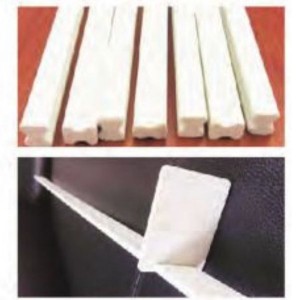

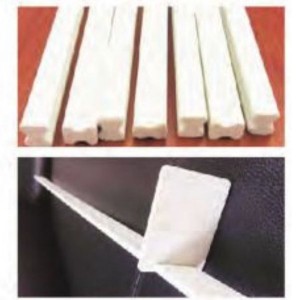

I-shaped Struts

Glass pultrusion struts, also known as l-shaped strips, drawing strips, venting strips, etc., are made of non-alkali glass fiber impregnated thermosetting resin by a pultrusion process, which has high mechanical strength, excellent electrical properties, and flame retardant. Corrosion resistance, arc resistance and other advantages. Mainly used for dry-type transformer interlayer ventilation and cooling, reactor and wave blocker.

-

Ama Insulation Paper

AMA is a new type of electrical insulating material made of polyester film and two layers of imported high-quality cable paper, and then the special modified epoxy resin is evenly coated on the AMA. It is mainly used for oil-immersed transformers to replace the original insulation materials and enhance the interlayer insulation perfor mance.

-

Insulation mesh netting

The mesh fabric adopts high-quality raw materials and uses advanced production technology. The mesh fabric has impregnation, no air bubbles inside, no partial discharge, high insulation level, and its temperature resistance level can reach “H” level, not only in It has high mechanical strength at normal temperature and high mechanical strength at high temperatures. It ensures that the pouring transformer and reactor can operate normal at high temperatures.

-

Composite Pet Board

The electric composite composite panel is made of multi-layer composite of high-temperature adhesive coated with polyester film. It has good mechanical properties, electrical properties, shrinkage, hygroscopicity and reliable heat resistance. It is mainly used for dry transformer high and low voltage. Insulation between coils, can be used as an insulating cylinder and end insulation instead of epoxy resin board, phenolic resin board.

-

Phenolic Paper Tube

It has certain insulation and mechanical strength and is suitable for insulating structural parts of electrical equipment.